Cutting intricate designs and shapes into wood, metal, or plastic is a skill that many DIY enthusiasts and professionals strive to master. The jigsaw is the ideal tool for this task, capable of cutting complex shapes with precision. However, jigsaw blades control is the key to success when using a jigsaw, as the fine details and smooth edges often define the quality of the work.

In this article, we will dive into how to use a jigsaw to cut complex shapes while maintaining blade control and minimizing mistakes. We will also cover useful tips, blade selection, and frequently asked questions to help you achieve the perfect cut every time.

Understanding the Jigsaw: A Brief Overview

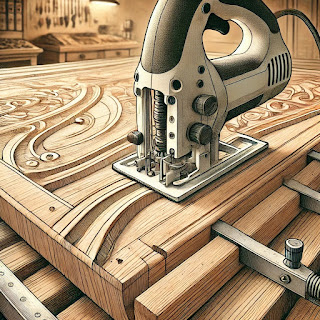

A jigsaw is a versatile handheld power tool that uses a reciprocating blade to make curved cuts, straight cuts, or bevels. Its ability to create complex shapes makes it popular among carpenters, hobbyists, and DIYers. However, the outcome of your project heavily relies on blade selection, speed, and cutting technique.

Blade Selection: Choosing the Right Tool for the Job

The first step to mastering blade control with a jigsaw is understanding the blade. Different materials require different blades, and the blade's quality can make or break your project. Here are some tips on choosing the right jigsaw blade:

Tooth Count (TPI): The number of teeth per inch (TPI) impacts the smoothness of the cut. A higher TPI, such as 12–32 TPI, works better for metals and plastics, offering finer cuts. For wood, a lower TPI (6–12 TPI) is sufficient for faster cuts, though they may not be as smooth.

Material Type: Blades are made from different materials. High-carbon steel (HCS) blades are best for softwoods, while bi-metal blades work well with harder woods and metals. Tungsten-carbide blades are designed for extremely tough materials such as tiles or metals.

Blade Width: Narrower blades offer greater flexibility for making tighter curves. However, they are more prone to breaking, especially if the material is thick or tough. Wider blades are better for long, straight cuts.

Cutting Techniques: Tips for Controlling the Jigsaw

Here are some expert tips for improving your blade control when cutting complex shapes:

1. Clamp the Workpiece Securely

Before you even start cutting, make sure your material is securely clamped down to avoid slipping or vibrations. Vibration can lead to imprecise cuts, especially when working on intricate designs.

2. Mark the Cutting Line Clearly

Use a pencil or marker to draw the design or shape on your material. Ensure that the lines are easy to follow while cutting, especially for more complicated shapes. For better accuracy, use a stencil or a guide.

3. Choose the Right Speed

Adjusting the jigsaw's speed based on the material and the intricacy of the shape is crucial. Faster speeds work better for softwoods and straight cuts, but when working on detailed designs or harder materials, lower speeds give you more control.

4. Start with a Pilot Hole

For internal cuts, drill a pilot hole with a drill bit larger than your jigsaw blade to help guide your blade into the material. This method ensures a clean starting point without compromising the rest of the material.

5. Keep the Jigsaw Moving Slowly

Avoid rushing the cut by forcing the jigsaw too quickly through the material. A slow, steady pace ensures more precise cuts and prevents overheating the blade, which can lead to warping or breakage.

6. Control the Blade on Tight Curves

When navigating tight curves, you may need to pull the blade back and reposition it frequently to avoid bending or snapping. Forcing the blade through a sharp turn often leads to poor-quality cuts and potential damage to the blade.

7. Keep the Base Plate Flat

To maintain stability, always keep the base plate of the jigsaw flat against the material. This reduces the risk of the blade wandering off track and ensures a clean, accurate cut.

8. Make Use of Bevel Cuts

For more advanced projects, you might need to make bevel cuts. Most jigsaws allow you to tilt the base plate at angles up to 45 degrees. Bevel cuts add complexity but offer more creative flexibility, especially when crafting pieces that need to fit together at specific angles.

Safety Tips When Using a Jigsaw

- Wear Safety Gear: Always wear safety goggles to protect your eyes from sawdust and debris. Ear protection is also recommended if you’re using the jigsaw for extended periods.

- Unplug the Jigsaw When Changing Blades: Never attempt to change blades while the jigsaw is still plugged in or while the blade is hot.

- Use the Right Blade for the Material: Always ensure that you're using the correct blade to prevent damage to the material or the blade.

Common Mistakes and How to Avoid Them

1. Forcing the Jigsaw

Many beginners make the mistake of forcing the jigsaw through the material, which leads to rough edges or broken blades. Let the blade do the work, and focus on guiding it smoothly through the material.

2. Choosing the Wrong Blade

Using a blade with the wrong TPI or material can ruin the cut. Double-check that your blade matches the type of cut and material you’re working on.

3. Skipping the Pilot Hole

Attempting to cut internal shapes without starting with a pilot hole can cause the blade to veer off-course, resulting in inaccurate cuts.

FAQ: Cutting Complex Shapes with a Jigsaw

Q1. What’s the best jigsaw blade for cutting tight curves?

A fine-tooth blade with a narrow width is best for cutting tight curves, as it allows for better maneuverability. Look for blades with a higher TPI, such as 20–24 TPI, for smoother cuts in delicate materials.

Q2. Can I use a jigsaw to cut metal?

Yes, but you’ll need a bi-metal blade or one made specifically for cutting metal. Ensure that you lower the speed setting and use lubricant to reduce friction and overheating.

Q3. How can I avoid chipping when cutting plywood?

To avoid chipping on plywood, use a fine-tooth blade, such as a reverse-tooth blade, which cuts on the downstroke, minimizing the risk of splintering the top layer of plywood.

Q4. What is the ideal speed for cutting intricate designs?

Lower speeds (setting 1 or 2 on most jigsaws) give you more control when working with intricate designs, as they allow for more precise blade movement.

Q5. How do I reduce vibration when cutting?

To reduce vibration, make sure the material is clamped securely, and keep the base plate of the jigsaw flat against the surface. A slow, steady hand helps maintain better control over the tool.

Conclusion

Mastering the art of cutting complex shapes with a jigsaw requires patience, practice, and the right techniques. By selecting the appropriate blade, controlling the speed, and following proper safety protocols, you can achieve professional-looking results, whether you're crafting furniture, art pieces, or detailed woodworking projects.

Comments

Post a Comment