Introduction

Welcome to the world of sigma cut tiles, where precision meets elegance to redefine your living spaces. In this article, we'll delve into the intricate details of sigma cut tiles, exploring their design, application, and the unique charm they bring to any environment.

Sigma Cut Tile: Redefining Precision

1. Understanding Sigma Cut Tile

Sigma cut tiles are more than just flooring solutions; they are a testament to precision engineering. Each tile undergoes a meticulous cutting process, ensuring uniformity and perfection in every piece. The result? A flooring option that exudes sophistication.

The allure of sigma cut tiles lies in the attention to detail during the cutting process. The precision achieved is unparalleled, making them a top choice for those who appreciate perfection in design.

2. The Art of Precision Cutting

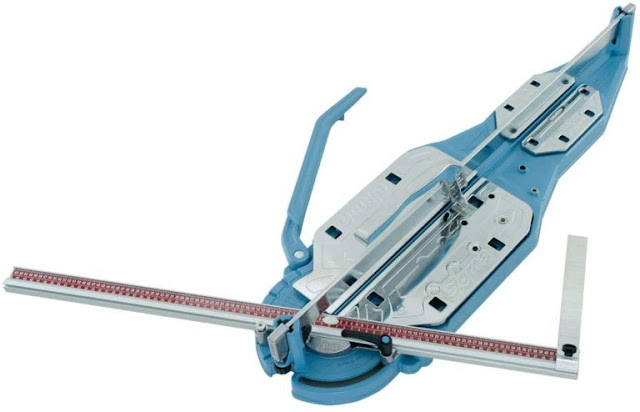

At the heart of sigma cut tiles is the art of precision cutting. Advanced cutting techniques, coupled with state-of-the-art machinery, create tiles with sharp, clean edges. This precision not only enhances the aesthetics but also facilitates seamless installation.

The precision cutting process is a blend of technology and craftsmanship, producing tiles that fit together flawlessly. The result is a visually stunning and structurally sound surface.

3. Versatility in Design

Sigma cut tiles offer a diverse range of design possibilities. From classic patterns to intricate mosaics, the versatility of these tiles allows for creative expression in various spaces. Whether it's a residential home or a commercial establishment, sigma cut tiles elevate the aesthetic appeal.

Transform your space with sigma cut tiles that transcend the ordinary. The versatility in design opens up a world of possibilities for creating unique and captivating interiors.

Sigma Cut Tile in Action

4. Residential Elegance with Sigma Cut Tiles

Immerse your home in luxury by choosing sigma cut tiles for your living spaces. The precision and elegance they bring redefine the concept of home decor, creating an ambiance that is both welcoming and sophisticated.

Elevate the elegance of your home with sigma cut tiles. The precision-cut designs add a touch of luxury to your living spaces, making a lasting impression on residents and guests alike.

5. Commercial Brilliance

In the commercial realm, first impressions matter. Sigma cut tiles make a statement of excellence, turning ordinary spaces into showcases of brilliance. From lobbies to boardrooms, these tiles redefine the perception of corporate interiors.

Impress clients and visitors with the brilliance of sigma cut tiles. The precision and sophistication they exude contribute to a professional and upscale atmosphere in any commercial setting.

Sigma Cut Tile: FAQs Unveiled

What makes sigma cut tiles different from traditional tiles?

Sigma cut tiles stand out due to their precision cutting process, ensuring sharp edges and a seamless fit during installation. This sets them apart from traditional tiles, providing a level of sophistication unmatched in the world of flooring.

Are sigma cut tiles suitable for high-traffic areas?

Absolutely. The precision cutting not only enhances aesthetics but also contributes to the durability of sigma cut tiles. They are an excellent choice for high-traffic areas, maintaining their elegance even in busy spaces.

Can sigma cut tiles be used outdoors?

While sigma cut tiles are primarily designed for indoor use, certain varieties with suitable finishes can be used in outdoor settings. It's essential to choose the right type to ensure longevity and performance in exterior applications.

Do sigma cut tiles require special maintenance?

Maintaining sigma cut tiles is relatively straightforward. Regular cleaning with a mild detergent is usually sufficient to preserve their beauty. However, it's advisable to follow the manufacturer's guidelines for specific care instructions.

Are sigma cut tiles cost-effective?

While sigma cut tiles may have a higher initial cost, their durability and timeless appeal make them a cost-effective choice in the long run. The investment pays off in terms of aesthetics, longevity, and overall value.

Can sigma cut tiles be installed without professional help?

While some DIY enthusiasts may attempt sigma cut tile installation, it's recommended to rely on professional installers. The precision required during installation demands expertise to ensure a flawless and lasting result.

Conclusion

In conclusion, sigma cut tiles redefine the standards of precision and elegance in the world of flooring. From residential spaces to commercial establishments, these tiles bring a touch of sophistication that captivates and endures. Elevate your surroundings with the timeless charm of sigma cut tiles.

Sigma Title Cutter

Comments

Post a Comment