Introduction

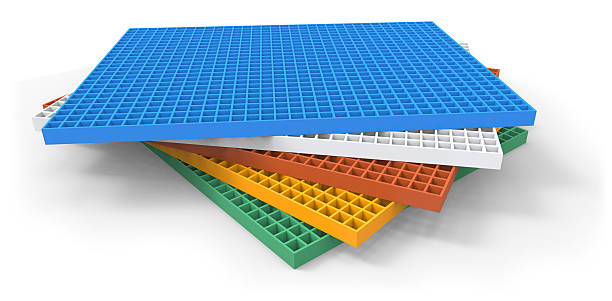

Welcome to the world of Fiber Reinforced Plastic (FRP) grating, a versatile and innovative solution with diverse applications. In this article, we will explore the wide range of applications of FRP grating, shedding light on its uses across various industries and sectors.

Understanding FRP Grating

To comprehend the applications fully, it's essential to understand the composition of FRP grating. Comprising reinforced fibers embedded in a polymer matrix, FRP grating boasts remarkable strength and durability.

FRP Grating Composition

Notable Properties

The unique properties of FRP grating, including corrosion resistance, high strength-to-weight ratio, and durability, contribute to its widespread use in various industries.

Key Advantages

Explore the key advantages of FRP grating, such as its low maintenance requirements, cost-effectiveness, and adaptability to different environmental conditions.

Applications in Industrial Sector

Discover how FRP grating finds extensive applications in industrial settings, providing a reliable solution for flooring, walkways, and platforms.

Use in Chemical Processing

Learn about the crucial role FRP grating plays in chemical processing industries, where its resistance to chemical corrosion is invaluable.

FRP Grating in Oil and Gas Industry

Delve into the applications of FRP grating in the oil and gas sector, where its non-conductive and non-sparking nature is paramount for safety.

Impact in Water Treatment Plants

Uncover the importance of FRP grating in water treatment plants, where its resistance to moisture and chemicals is advantageous.

FRP Grating in Marine Environments

Explore how FRP grating contributes to marine environments, providing a durable and corrosion-resistant solution for various structures.

Applications in Construction

In the construction industry, FRP grating is employed for its versatility and strength in diverse applications.

Architectural Uses

Learn about the creative architectural uses of FRP grating, enhancing the aesthetic appeal of structures.

FRP Grating in Transportation

Discover how FRP grating is utilized in transportation infrastructure, offering lightweight and durable solutions.

Versatility in Walkways and Platforms

Explore the versatility of FRP grating in the creation of walkways and platforms, ensuring safety and longevity.

Agricultural Applications

In the agricultural sector, FRP grating finds applications in diverse areas, showcasing its adaptability.

FRP Grating in Renewable Energy

Learn about the role of FRP grating in the renewable energy sector, where its durability and corrosion resistance are crucial.

Role in Electrical and Telecommunication

Understand how FRP grating is integrated into electrical and telecommunication installations for enhanced safety.

FRP Grating in Residential Spaces

Discover the growing use of FRP grating in residential settings, adding both functionality and aesthetics.

Creative Uses in Art and Design

Explore the artistic applications of FRP grating in design and sculpture, showcasing its versatility.

Factors Influencing FRP Grating Selection

Understand the key factors influencing the selection of FRP grating for various applications.

FAQs

Q: Is FRP grating suitable for outdoor applications?

A: Yes, FRP grating is highly suitable for outdoor use due to its resistance to weather conditions and corrosion.

Q: Can FRP grating be customized for specific projects?

A: Absolutely, FRP grating can be customized in terms of size, color, and surface pattern to meet the specific requirements of a project.

Q: What maintenance is required for FRP grating?

A: FRP grating requires minimal maintenance, usually limited to regular cleaning to remove dirt and debris.

Q: Is FRP grating environmentally friendly?

A: Yes, FRP grating is considered environmentally friendly as it is recyclable and has a longer lifespan than many traditional materials.

Q: How does FRP grating compare to traditional materials like steel?

A: FRP grating offers advantages over traditional materials, including corrosion resistance, lower weight, and ease of installation.

Q: Can FRP grating be used in corrosive chemical environments?

A: Indeed, FRP grating is an excellent choice for corrosive chemical environments due to its resistance to chemical corrosion.

Conclusion

In conclusion, the applications of FRP grating are vast and varied, spanning industries and creative endeavors. Its unique properties and adaptability make it a go-to solution for architects, engineers, and artists alike. Embrace the future of materials with FRP grating.

Comments

Post a Comment